Rolled Ring Forging and Ring Rolling Machine Are on the Rise

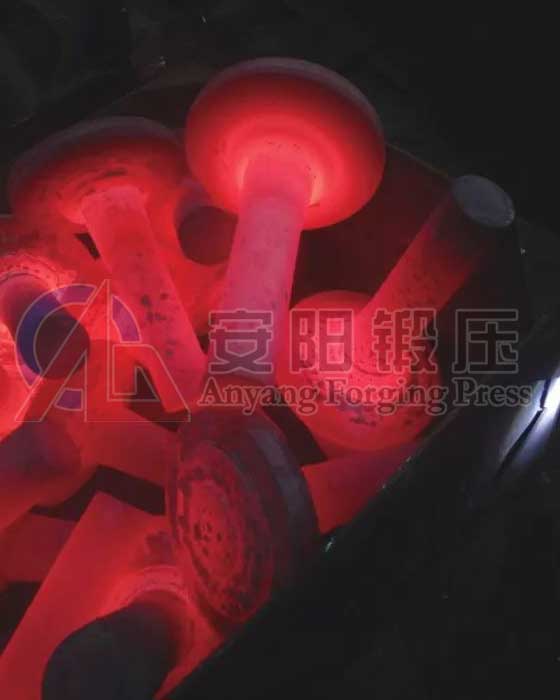

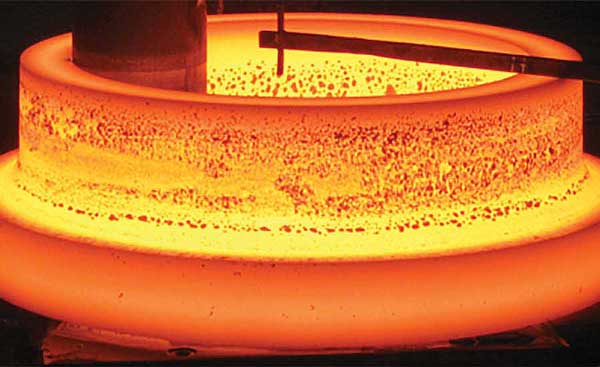

2019-12-07 14:13:09Rolled ring forgings are a product of the forging industry, a type of forgings. It is a metal ring (not including sheet material) which is an annular object that is subjected to external force by plastic deformation. This force is typically achieved by using a forging hammer, pressure, or a ring rolling machine. The ring rolling process creates a delicate grain structure and improves the physical properties of the metal. Rolled ring forgings can be seen everywhere in daily life and are an industrial product.

Application of Rolled Ring Forgings

Rolled Ring Forgings in Diesel Engine

A type of diesel engine forgings. Diesel engines are a type of power machinery that are commonly used as engines. Taking large diesel engines as an example, the forgings used are cylinder head, main journal, crankshaft end flange output end shaft, connecting rod, piston rod, piston head, crosshead pin, crankshaft transmission gear, ring gear, intermediate gear and oil pump more than ten species such as body.

Marine Rolled Ring Forgings

Marine forgings are divided into three categories, mainframe forgings, shafting forgings and rudder forgings. The main engine forging is the same as the diesel engine forging. Shafting forgings include thrust shafts, intermediate shafts and stern shafts. Rudder forgings include rudder stock, rudder stock, and rudder pin.

Weapon Rolled Ring Forgings

Forgings occupy an extremely important position in the weapon industry. By weight, 60% of the tanks are forgings. Gun barrels, muzzle brakes and tails in artillery, rifled barrels and triangular bayonet blades, rocket and submarine deep-water bomb launchers and mounts in infantry weapons, stainless steel valve bodies for high pressure coolers of nuclear submarines, shells, Bullets, etc., are forged products. In addition to steel forgings, weapons are also made from other materials.

Petrochemical Rolled Ring Forgings

Forgings are widely used in petrochemical equipment. Such as manholes and flange rolled ring forgings for spherical storage tanks, various tube plates required for heat exchangers, whole forged cylinders (pressure vessels) for catalytic cracking reactors for butt-welded flanges, tube joints for hydrogenation reactors, and fertilizers The top cover, bottom cover and head required by the equipment are forgings.

Mining Rolled Ring Forgings

According to the weight of the equipment, the proportion of forgings in the mining equipment is 12-24%. Mining equipment includes: mining equipment, hoisting equipment, crushing equipment, grinding equipment, washing equipment, sintering equipment.

Nuclear Power Rolled Ring Forging

Nuclear power is divided into two types: pressurized water reactor and boiling water reactor. The main large forgings of nuclear power plants can be divided into two categories: pressure shells and reactor internal components. Pressure shell contains: cylinder flange, nozzle section, nozzle, upper cylinder, lower cylinder, cylinder transition section, bolts, etc. The internal components of the reactor work under severe conditions such as high temperature, high pressure, strong neutron radiation, boric acid water corrosion, scouring and hydraulic vibration, so 18-8 austenitic stainless steel is used for production.

Thermal Power Rolled Ring Forgings

There are four key forgings in thermal power generation equipment, namely the rotor and guard ring of the turbine generator, and the impeller and turbine rotor in the steam turbine.

Hydroelectric Rolled Ring Forgings

Important forgings in hydroelectric power station equipment include hydro turbine shafts, hydro-generator shafts, mirror plates, thrust heads, etc.

Rolled Ring Forging Industry Is on the Rise

In recent years, China's rolled ring forging industry has implemented product structure adjustments in related industries such as power, metallurgy, and petrochemicals, increased product added value, transformed and eliminated high-pollution, high-energy-consumption, and low-efficiency equipment, and invested in large-scale equipment that is efficient, energy-saving, and environmentally friendly China has been given the opportunity for rapid development. The policy of correcting the development mode that depends on resources and sacrificing the environment, and vigorously develops renewable energy sources such as nuclear power and wind power have provided a good opportunity for the development of large-scale forgings.

The production of the entire rolled ring forging industry has been on a rising trend for several consecutive years, and product supply is in short supply, especially key large forging products show a worldwide shortage. Enterprises with large forging manufacturing resources have become important resources competing for the world. The economic benefits of the entire industry have improved significantly, and the industry has received a rare development opportunity. The product output, new product development output value, and main economic indicators of the industry have hit a record high for China's large forging industry.

Ring Rolling Machine for Sale

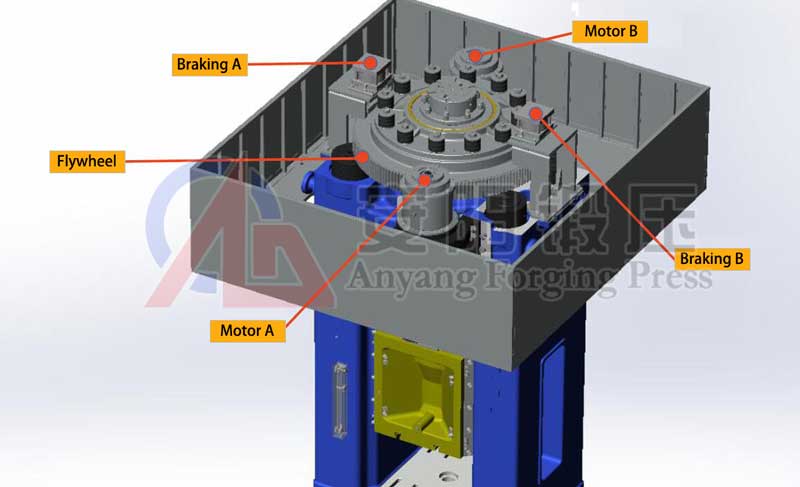

There are two type of ring rolling machine vertical ring rolling machine and horizontal ring rolling machine.

D51 Horizontal Ring Rolling Machine

D51 ring rolling machine is suitable for production of rings in the field of automobile, machinery, oil&gas, chemical etc, it can produce the rings with rectangular cross-section and special section such as bearing rings, gear banks, flat flanges, weld-neck flanges etc, with features of once rolling, higher production efficiency, higher precision blanks.

| Item | Unit |

D51- 160D |

D51- 160E |

D51- 250D |

D51- 250E |

D51- 350D |

D51- 350E |

D51- 400E |

D51- 500E |

D51- 630E |

D51- 800E |

D51- 1000E |

D51- 1000F |

| Max. OD of ring | mm | 160 | 200 | 250 | 300 | 350 | 350 | 400 | 500 | 630 | 800 | 1000 | 1200 |

| Min. OD of ring | mm | 45 | 50 | 80 | 100 | 120 | 120 | 140 | 160 | 180 | 200 | 220 | 250 |

| Max. ID of ring | mm | 140 | 180 | 230 | 280 | 310 | 310 | 360 | 460 | 590 | 740 | 940 | 1100 |

| Min. ID of ring | mm | 30 | 40 | 60 | 80 | 100 | 100 | 120 | 120 | 160 | 180 | 200 | 220 |

| Width of ring | mm | 35 | 70 | 50 | 120 | 85 | 220 | 220 | 220 | 200 | 220 | 220 | 200 |

| 250 | 350 | 350 | 350 | ||||||||||

| Max. Productivity | Pcs/h | 700 | 600 | 500 | 240 | 200 | 120 | 100 | 90 | 80 | 60 | 50 | 40 |

| Nominal pressure of cylinder | kg | 6000 | 11300 | 9800 | 19600 | 15500 | 30000 | 32000 | 38000 | 38000 | 42000 | ||

| 42000 | |||||||||||||

| Max. slide stroke | mm | 70 | 70 | 110 | 110 | 130 | 130 | 130 | 130 | 200-350 | |||

| 250 | 250 | 250 | |||||||||||

| Roller line speed | m/sec | 2~2.5 | 1.64 | 2.1 | 1.63 | 2.2 | 1.45 | 1.45 | 1.5 | 1.47 | 1.5 | 1.5 | 1.5 |

| Main shaft speed | r.p.m | 120 | 92 | 80 | 62.3 | 62 | 41 | 40 | 40 | 38 | 38 | 38 | 38 |

| OD of rolling wheel | mm | 360~380 | 500~520 | 680~700 | 680~700 | 700~720 | 700~720 | 700~720 | 760~820 | 760~820 | 820 | ||

| Center height of rolling roller | mm | 670 | 670 | 875 | 875 | 1050 | 1100 | 1100 | 1200 | 1250 | 1350 | 1600 | 1780 |

|

Min. distance between rolling wheel′s center and rolling roller′s center |

mm | 185 | 185 | 265 | 265 | 365 | 365 | 375 | 375 | 385 | 410 | 410 | 410 |

| Main motor power | KW | 18.5 | 30 | 37 | 55 | 75 | 90 | 90 | 90 | 90 | 110 | 110 | 132 |

| 110 | 132 | 132 | 160 | ||||||||||

| Hydraulic motor | KW | 4 | 7.5 | 11 | 11 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| 18 | 18 | 18 | |||||||||||

| Outsize of machine | mm |

2200× 1550× 1850 |

2350× 1700× 2100 |

2890× 1900× 2400 |

3440× 2000× 2700 |

4040× 2000× 3000 |

4595× 2050× 3370 |

4595× 2100× 3370 |

4800× 2200× 3470 |

4800× 2300× 3770 |

4800× 2350× 3770 |

5000× 2400× 3520 |

5500× 2700× 4200 |

| Weight of machine tool | kg | 3200 | 3500 | 7000 | 7800 | 12000 | 15000 | 15800 | 16500 | 17000 | 22000 | 24000 | 25000 |

D53 CNC Radial And Axial Horizontal Ring Rolling Machine

D53 series horizontal ring rolling machine is adopted CNC technology to roll the ring from radial and axial together. It is used to produce large size rings such as bearings, flanges and ball valves.

| Item | Unit |

D53K- 630 |

D53K- 1000 |

D53K- 1600 |

D53K- 2000 |

D53K- 2500 |

D53K- 3000 |

D53K- 3500 |

D53K- 5000 |

D53K- 6300 |

D53K- 8000 |

D53K- 9000 |

D53K- 10000 |

D53K- 12000 |

|

|

Machine parater |

Radial force |

KN | 630 | 800 | 1250 | 1600 | 2000 | 2000 | 2000 | 2500 | 4000 | 6300 | 8000 | 10000 | 16000 |

|

Axial force |

KN | 500 | 630 | 1000 | 1250 | 1250 | 1600 | 1600 | 2000 | 3150 | 4000 | 5000 | 6300 | 8000 | |

|

Angel of taper roller |

° | 30 | 30 | 40 | 30 | 35 | 35 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | |

|

Rolling line speed |

m/s | 1.5 | 1.3 / 0.5~1.4 | ||||||||||||

|

Drive power |

Radial motor |

KW | 160 | 200 | 280 | 2×200 | 2×250 | 2×315 | 2×280 | 2×400 | 2×500 | 2×690 | 2×900 | 2×1250 | 2×2000 |

|

Axial motor |

KW | 2×75 | 2×110 | 2×160 | 2×200 | 2×220 | 2×315 | 2×280 | 2×400 | 2×500 | 2×600 | 2×800 | 2×1000 | 2×1300 | |

|

Brouching dimension |

OD of roller |

mm |

300~ 630 |

400~ 1000 |

500~ 1600 |

600~ 2000 |

600~ 2500 |

600~ 3000 |

700~ 3500 |

800~ 5000 |

900~ 6300 |

1000~ 8000 |

1100~ 9000 |

1250~ 10000 |

1500~ 12000 |

|

Spacing distance of taper rollers |

mm |

40~ 300 |

50~ 400 |

60~ 500 |

80~ 550 |

80~ 550 |

80~ 650 |

80~ 650 |

90~ 800 |

100~ 1000 |

110~ 1350 |

110~ 1600 |

120~ 1800 |

130- 2000 |

|

|

Machine capacity |

Max rolling height |

mm | 200 | 300 | 400 | 450 | 500 | 500 | 500 | 650 | 900 | 1200 | 1450 | 1650 | 2000 |

|

Max width of billet |

mm | 150 | 180 | 200 | 350 | 300 | 400 | 420 | 500 | 700 | 800 | 850 | 1000 | 1200 | |

|

Max width of product |

mm | 90 | 110 | 120 | 200 | 150 | 220 | 250 | 300 | 420 | 480 | 530 | 600 | 700 | |

|

Machine outsize |

Length | mm | 9500 | 10500 | 11000 | 13500 | 14500 | 18000 | 19000 | 21000 | 25000 | 32000 | 36000 | 40000 | 47000 |

| Width | mm | 2100 | 2300 | 2500 | 2400 | 3500 | 3500 | 3400 | 4500 | 5800 | 6500 | 7500 | 8000 | 10000 | |

|

Height from ground |

mm | 3000 | 3500 | 4300 | 5200 | 5000 | 5500 | 5800 | 6200 | 7200 | 9400 | 10000 | 10500 | 11500 | |

Make Large Flange Rolled Rings in Belgium

Anyang Ring Rolling Machine and Pneumatic Forging Hammer Working in Romania